What Suppliers Don’t Know is Hurting Your Business

In my recent trip to China this April I attended the Canton Fair for my third time. I met with dozens of Suppliers with varying levels of sophistication from Suppliers who have dealt with the largest retailers in the world to Suppliers who couldn't speak a word of English. But no matter what level of sophistication the Suppliers had it struck me that there are three business concepts that are extremely important to Western buyers that very few Chinese Suppliers get. Here's are those three things and what you need to do to make sure your Supplier's lack of knowledge doesn't hurt your business.

Chinese Suppliers Don't Understand We Prefer Low MOQs Over Color Boxes

You want to know a hack? Often Chinese Suppliers quote you ridiculously high MOQs because of the packaging that they outsource, not because of the products they produce. Almost all Chinese Suppliers have to purchase their boxes and other packaging from another vendor. These vendors have MOQs for boxes, normally around 500 pieces. Therefore Suppliers will often quote MOQs for their products as 500 pieces simply because that's the MOQ for them to purchase boxes.

But wait – you don't mind if your item ships in a poly bag? Or a plain box with a sticker? Well, then the MOQ can be something way more reasonable like 50 pieces. If a color box is important to you, another possibility is to pay your Supplier a higher price per item for fewer items (essentially making up for the higher costs of boxes your Supplier will be paying).

When you’re first validating a product, you probably don’t care that much about a full color box. If you’re like me, on a first order you’d probably rather buy fifty $10 items in a plain box for $500 than five hundred $10 items for $5000 in a full color box. There's also cash flow considerations – you might be better off paying a higher price per item rather than having a bunch of cash tied up in a bunch of inventory.

Takeaway: Ask your Supplier what their MOQ is for just a plain cardboard box without any artwork or a packed in a poly bag. Alternatively, if full color boxes are important to you, offer to pay for the price of the boxes. In the Chinese Importing course, I discuss some strategies for creating both cheap and great looking packaging.

Chinese Suppliers Don't Understand Ecommerce Shipping Costs

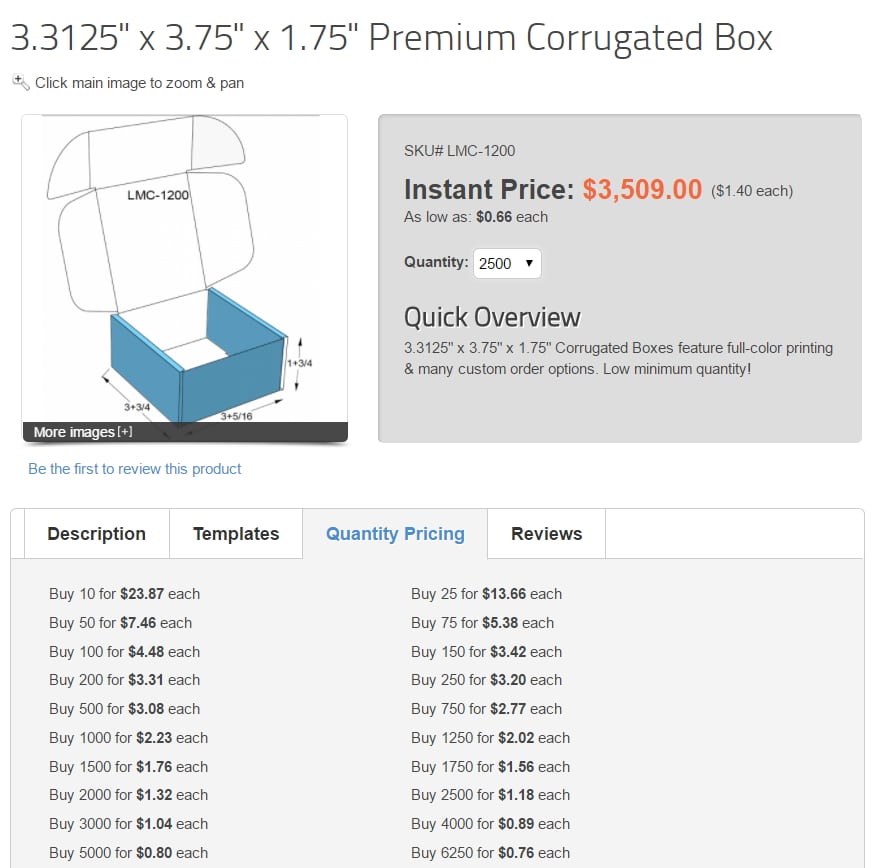

Chinese Suppliers understand shipping costs basically as the cost of shipping a container of goods to America and nothing more. In the vast majority of the time, they have little idea of how much shipping costs within America are, such as FBA fees. And of course, these shipping fees can make up a huge portion of your costs, often more than the product itself.

Chinese Suppliers understand the concept of sea freight quite well. They know it’s about $1000 to ship a 20’ container to Los Angeles. Therefore, in their minds, if they can fit 1000 items in a container, it’s only $1 in shipping costs! Of course, this is completely false. The cost of sea freight to ship 1000 bicycles might only be $1 each but the shipping costs of a bicycle in America for UPS Ground, USPS priority, etc. could be well over $50. Even though there’s fairly accessible tools available to calculate shipping costs in America, most Chinese Suppliers don’t quite understand domestic shipping costs.

Takeaway: The implication for importers is that you need to always assume that Chinese Suppliers are packaging your items in the absolute least economical way possible. Specifically bulky packaging that just barely moves an item into the ‘oversize' category for Amazon FBA. Packaging optimization is an easy way to create competitive advantage for your products.

Chinese Suppliers Don't Understand the Need for Instructions

I couldn’t believe how many times walking the Canton Fair that factories would gladly show me an item like a state of the art roof rack for a vehicle. The product would be perfect – constructed well and made of high quality materials. But they had absolutely no instructions for customers on how to mount the rack to a vehicle!

Would customers be able to figure this out after searching YouTube and using some ingenuity? Probably. But by the time they got done they’d probably be pissed off at you for selling them a roof rack without instructions even though the product itself was perfect.

Most factories in China only care about the product they’re producing. This sort of makes sense – they have a state of the art injection molding machine and that’s what they do well. Writing instructions? That's better left for the English speakers in the West.

Takeaway: Ask to see a copy of the instructions for a product before your Supplier ships the product. If you happen to find a Supplier that actually has instructions then expect to have to rewrite these instructions into readable English.

Conclusion

It's easy to assume that our Chinese Suppliers are manufacturers, marketers, and international market experts. The truth is that they often only excel in one of the three, typically manufacturing. Everyone always talks about reading bad reviews on Amazon for a product and applying those criticisms as design improvements to a product. That's ideal, but not always possible without huge investments of money into new tooling and molds. Optimizing packaging, writing clear instructions and creating killer packaging is attainable for most people and is a great way to create competitive advantage for your products.

In your experience, are there any other concepts that your Suppliers just don't get? Or have you experienced any of the three gaps in knowledge above? If so, share in the comments section below.