How to Conduct an E-Commerce Demand Forecasting to Avoid Stockouts and Dead Stock

Demand forecasting is the method by which businesses use historical sales data and other input to predict and prepare for future customer demand. It’s a way for businesses to know how much product to order and store so they never run out of offers while not tying in too much cash in inventory in the process.

If you’re an e-commerce business owner, you need to strike a balance between ordering enough so customers always have something to buy and not ordering too much that it accumulates unnecessary storage fees and cut into your profit margin.

Why Is Demand Forecasting Important?

When you’re in business, you need to make data-driven decisions. You can’t just produce a certain number of products and hope they all get sold or you don’t run out.

Here are just a few of the advantages of doing a demand forecast to plan your inventory.

Avoid stockouts. When you run out of inventory, you’re not only missing out on potential revenue. It can affect how your customers view your brand, and, depending on the platform you use, can affect your seller metrics as well.

Keep your customers. Let’s say your marketing efforts finally paid off, and you have return customers who are specifically looking for your brand and are searching for branded keywords. But because you ran out of inventory, they opted for your competitor’s product instead. You’ve effectively given your buyer over to your competition.

Avoid unnecessary storage fees. Overstocking is as bad as understocking. While the latter affects your brand image and seller metrics, overstocking affects your profit margin. Storing your products is not cheap, especially if they sit there for long periods. If you’re an Amazon FBA seller, for example, you have to deal with overage fees.

Improve production lead time. When you have an estimate of how much product you’re going to sell, it’s easier to plan out orders from your suppliers.

Things to Consider When Doing Demand Forecasting

Before we go into the steps, let’s look at some of the things you need to consider when you’re planning your order and inventory.

Nature of products. Is your product perishable? Does it have an expiration date? The immediacy of selling these products and the need to not overproduce and overorder are more than those that don’t spoil.

Product seasonality. Are you selling holiday-themed products? Seasonal products are more tricky to plan for since you need to have enough inventory just in time and sell them within the period when they’re in demand.

Lead times. Are you importing your products from China? How long does it usually take to arrive to your warehouse? Also, consider natural calamities and other factors that can affect your lead time. Cases like the Ever Given are exceptional, but it’s better to prepare for a similar occurrence.

Market size and location. If you sell in multiple countries or marketplaces, understand what product variety sells better in certain locations. Your customers in Country A may have different preferences than your buyers from Country B.

Politics. Like it or not, our relationship with other countries help determine whether or not it’s advantageous to source from them. For example, in 2023, Walmart increased its import from India and reduced its imports from China because of the Washington-Beijing tension. A change in manufacturer may affect how long your products arrive.

How to Conduct a Demand Forecast

Whether you’re running your e-commerce store or selling through Amazon FBA, these steps apply when you conduct a demand forecast.

Step 1: Define your forecast objectives.

Before you come up with a forecast, know your main objective. Are you doing a forecast of a particular product only? What exactly are you trying to accomplish with it? Is the forecast only for the last quarter or is it a year-long plan?

Defining your goals makes it easier for you to determine what data you need to gather and analyze.

Step 2: Choose a method of demand forecasting.

There are two main kinds of demand forecasting: quantitative and qualitative.

Qualitative forecasting is very helpful for businesses that are just starting out or for a newly launched product. In these cases, there isn’t enough historical sales data to come up with a good forecast.

Qualitative forecasting, on the other hand, involves analyzing trends and historical data to predict how much the demand will be in the coming months.

Step 3: Collect your data.

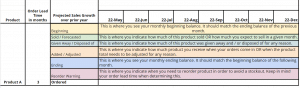

Now that you’ve determined what data you need, it’s time to gather the information and fire up Excel or Google Sheets. For our brands, we mainly use Google Sheets to easily share with other members of the team.

Step 4: Analyze data and make adjustments.

Once you see a pattern and determine how much inventory you’re going to need for the period you analyzed, make sure you order everything on time and take note of the considerations that you need to factor in to ensure you have just-in-time inventory.

Best Practices for Demand Forecasting in E-Commerce

Demand forecasting is especially important in e-commerce since running out of stock can lead your customers to competitors and overstocking can rake in a significant increase in storage fees.

Here are some of the best practices when you’re conducting a demand forecast.

Make sure you have a complete and correct picture. Make sure that the data you gather is complete and correct. There’s no point in making data-driven decisions if the data is wrong or incomplete. Consider all factors. Was there an event or a new policy that affected your sales? Will it likely affect your future sales?

Make adjustments for supply chain delays. Sometimes, it’s the weather. Sometimes, it’s human error. Other times, it’s getting through customs. Whatever it is, be wary of possible supply chain disruptions.

When the Ever Given was stuck in the Suez Canal for six days in 2021, it affected the delivery times of other cargo ships.

Keep updated with relevant information. Keep up with news that affects international trade and e-commerce in general. Subscribe to newsletters and find communities like EcomCrew Premium that meet regularly to keep you up-to-date with the latest e-commerce developments and strategies.

Final Thoughts

Creating a good demand forecast for your e-commerce business is a mix of art, science, and a bit of luck.

Anyone who’s into business always takes a certain level of risk, including under or overstocking. No matter how much you plan, there’s always the possibility of something going wrong that’s beyond your control. So continue adjusting and readjusting your business plans based on demand.

What are your top tips for conducting a demand forecast? Share it with us in the comments section.