5 Tips on How to Communicate Easily With a Factory

This article contains affiliate links that will allow us to earn commissions without any extra cost to you. Read our full disclosure here.

Unless you're sourcing from America, Canada, or another handful of English-speaking countries, you're almost certainly going to be dealing with a factory where English is not the native language. Even if you are dealing with a supplier in a country where English is the native language, working remotely leaves room for miscommunications to occur.

Here are five tips I learned over my 15 years of sourcing on how to improve communication with factories and suppliers.

Use more pictures and fewer words

There are over 7000 recognized languages in the world, but there's one form of communication that transcends borders and culture: pictures. We all know the age-old saying: “A picture is worth a thousand words” and when it comes to sourcing, a picture can be worth a thousand fewer headaches.

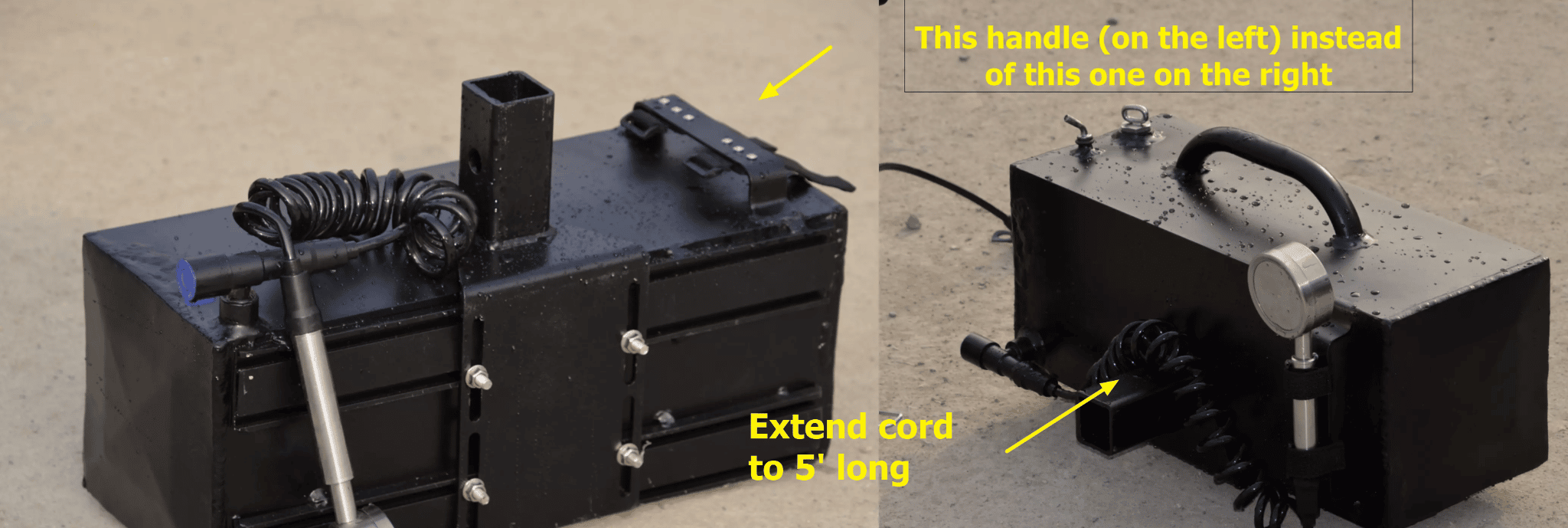

Whenever I'm communicating what kind of product I need, I always include a written summary of what I want to change AND include a picture with numerous annotations of the exact change I want as well. It doesn't need to be beautiful. , it's often a hodgepodge of arrows, sloppily drawn circles, and poorly copied-and-pasted graphics.

Larger companies may cringe at the idea of sending such poorly illustrated drawings but in my experience, entrepreneurs and small businesses often send bullet points and Skype messages more often than highly technical drawings. Quickly marking up photographs with arrows and text is a good method to eliminate a lot of miscommunications when dealing with suppliers abroad.

Assume nothing

I'll never forget one of my first really negative sourcing experiences back when I was still a university student. I had recently started my boating accessories business and was sourcing boat covers. I had worked with a supplier for a couple of orders on a product ambiguously described as ‘blue boat covers.' The products were selling well, and every time I had to restock, my purchase order was pretty much doubling in size from the previous one. After I received the third purchase order and started selling them, we started seeing some negative feedback from customers regarding the durability of the fabric we were using. Sure enough, when I compared the boat covers from my second purchase order with the most recent one, the fabric was significantly lighter and nowhere near as heavy-duty as the original ones.

I immediately emailed my supplier and asked them why they had substituted the fabric type on the latest purchase order. Their response? “You never specified which fabric type you preferred. We thought you would like this new lightweight fabric.”

This was a lesson learned: never leave anything open to interpretation. For every purchase order, specify clearly as many details as possible in your purchase order. What materials do you want to be used? What type of zippers? Is there any additional mounting hardware that should be included? How should it be packaged, both the inner packages and outer cartons? And so on and so forth. You can include these as notes on your purchase order or include a formal ‘tech pack' but one way or the other, specify as many details as possible to your supplier to avoid leaving room for decisions to be based on assumptions.

Hop on a video call with the production manager

When you're dealing with an overseas supplier, there's a high likelihood you're dealing with a fluent English-speaking sales or customer service representative. However, the production manager in charge of producing the container of dog beds you just ordered might not have the strongest English language skills. The result is an often-disastrous round of the ‘telephone game' except now with multiple languages involved: you're communicating something to a sales rep in English and your sales rep is translating it to your production manager in their native language. It normally works fine, but every now and then something gets completely lost in translation.

So, how can you solve this? For important orders, I ask to get on a video call with the sales rep and the production manager. The sales rep is still serving as the translator, but being on a video call with the production manager allows things to be elaborated and clarified more easily than if done through email. I and the production manager are still speaking different languages, but if I see an obvious look of confusion wash over the production manager, I know I need to elaborate and clarify things further.

Communicate in Your Supplier's Preferred App of Communication for Better Service

Whenever I travel, I'm always amazed at what each country uses as its preferred method of communication. In China, everything is done in WeChat. In South Korea, it's KaKao. In a lot of countries in Europe and even Asia, it's Messenger. I even see the changes in communication preferences when I make the 30-minute drive from my home in Vancouver, Canada to Washington State, USA. In Canada, WhatsApp is ubiquitous, but in the United States, it's not nearly as widely used.

The point is that it's different apps for different strokes. For many years, I more or less demanded that all of my suppliers dealt with me only through email. In my eyes, email gives such a cleaner and more organized record of communication than trying to communicate through an instant messaging app like WeChat. I even managed to get some suppliers on to BaseCamp (our project management software). My suppliers were happy to oblige to any of my communication preferences – as long as I was paying the bills, they'd be happy to communicate with me with carrier pigeon if I wanted!

OR 10% OFF Every Month When You Use Code: ECOMCREW10

Visit the supplier in person

For multiple years during the pandemic, visiting a supplier was essentially not possible. This was a shock for me personally. Each year, I would take at least two trips a year to visit even my smallest suppliers in Asia. It was a great way to build rapport and get things done quickly. Basically, I knew any major production problems we encountered could be resolved just by sitting down with the supplier over a day or two at their factory.

My company managed to survive the pandemic. But we had to learn to communicate entirely remotely and using the communication techniques I've discussed in this article became crucial. But over the last couple of years, I've seen problems, some small and some big, start to creep in that I know could be resolved quickly over a few cups of tea.

Thankfully, the worst of the pandemic (knock on wood) seems to be behind us and countries are starting to slowly open up. Countries have various degrees of travel restrictions and people have varied feelings about how safe it is to travel again, but things feel like they are returning to normal again. The pandemic has put a lot of strain on people's relationships, whether with friends, family, or, in this case, suppliers. When you are able to and when you feel comfortable enough again, it's worth taking the opportunity to get off Facetime and reconnect with your supplier for some long overdue face-to-face time. Your business health, and maybe even your own health, maybe all the better for it too.

I hope you enjoyed this article. If you've learned any techniques for better communication with your suppliers drop your thoughts in the comments section below.