How to Avoid Crappy Products When Importing from China

In part 1 of this mini-series, I discussed how to avoid scams but I also emphasized that scams are incredibly rare when importing from China.

However, as rare as scams in China may be, poor quality products are equally as common. If you're an Amazon seller, all of your efforts to try and get positive product reviews through things like email auto-responders and packaging inserts will be in vain if you have crappy quality products. So in this article, I am going to discuss how to avoid crappy quality products and what you can do when this happens.

Types of Mistakes You'll Encounter

The first thing you need to be aware of the type of mistakes you will encounter when importing from China. These types of mistakes basically fall into one of two categories:

Deliberate Mistakes

You may or may not recall the tragedy China had a few years back in 2008 when a Chinese Supplier was found guilty of putting melamine in baby formula. Melamine was illegally added to baby formula and over 50,000 babies ended up being hospitalized.

Did the Chinese Supplier think that he would end up serious harming thousands of babies? Maybe, but more than likely he was just employing a cost cutting measure to get ahead in the ever competitive baby formula niche. This is the problem that importers face when importing from China: Suppliers may employ cost cutting measures when manufacturing products hoping that the buyers and their customers won't notice. This normally happens over a long period of time and is called quality fade.

The truth is, sometimes you won't notice when your Supplier starts cutting corners but other times you will. You can never be sure if that corner cutting will result in a completely defective product or, worse, hurting someone so you need to put measures in place to avoid this from happening.

Non-Deliberate/Careless Mistakes

The other type of mistakes you need to avoid are the ones your Supplier doesn't even realize they're making. For example, you order 100 sets of shoes and you receive 50 shoe boxes with right shoes and 50 boxes of shoes with left shoes. Does your Supplier get any advantage from doing this? None at all – it's just a careless mistake the result of poor quality assurance, both from you and your Supplier.

How to Avoid All Types of Mistakes

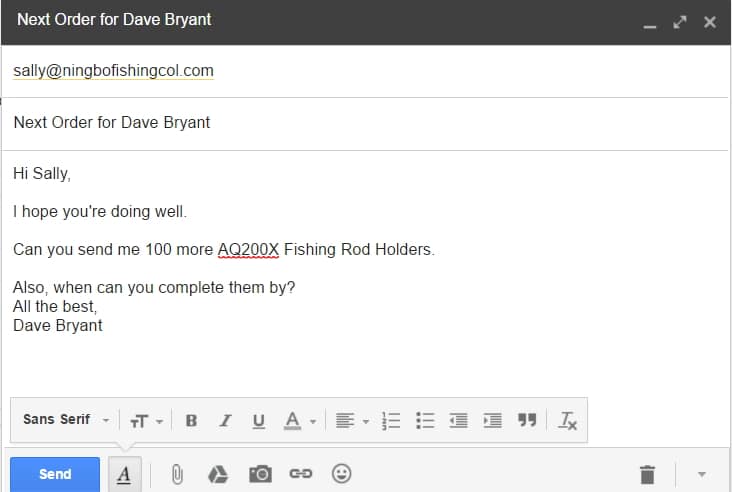

For a lot of importers, quality issues start the second they make an order. For most importers, placing an order looks a little bit like the following:

This isn't enough! I can assure you that at some point Mr.Dave Bryant is going to receive some crappy AQ200X fishing rod holders.

You can do better quality assurance than the vast majority of other sellers out there by doing the following steps:

- Understand the fair value of the product (get multiple quotes)

- Send an actual Purchase Order, not simply an email.

- Send a Product Specification document.

- Perform a random Third Party Inspection.

- Review your order, identify flaws/weaknesses in the products and continually revise your Product Specifications document.

Understand the Fair Value of the Product

You know already that you should always be getting three quotes or more for a product to find out the true market price of that product. Chinese manufacturing is ultra-competitive and two identical products will almost always be priced similarly, normally within 5-10% of each other. If there is more than a 10% difference between quotes then it is almost certainly because the products and quotes are not identical. Imagine you receive three quotes for a fishing rod holder:

- First quote: $12.00

- Second quote: $12.25

- Third quote: $9.50

For the third quote, there is likely something different about the quote or the product. Either it is constructed of different materials, the item is physically different, the shipping terms are different, the MOQ is much higher, etc. No matter what the difference is, you have not magically found a great Supplier with increased production efficiency.

You do not want to make the mistake of picking the cheapest quote and receiving an inferior product that will get poor reviews on Amazon and hurt your sales.

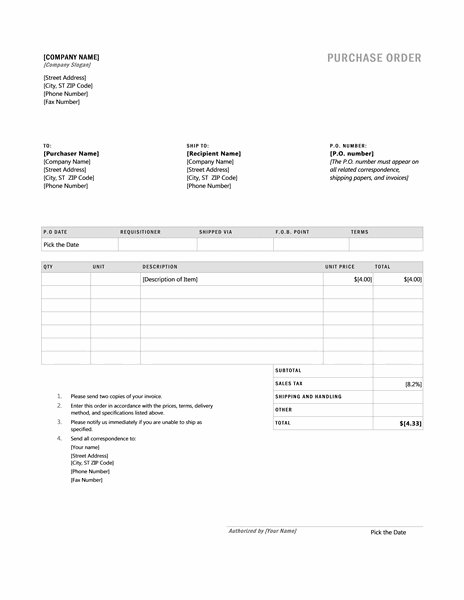

Send a Purchase Order

When you send orders to Suppliers do you simply send emails? Don't feel ashamed – most people do. But you shouldn't. You need to send an actual Purchase Order. There's a million sample Excel Templates online. In my course, I give you a sample template that includes some very China specific information for your Purchase Orders that will get your orders quicker and with less problems. Obviously you should buy my course (I could be biased though) but any purchase order is going to make you come across much more professional and as someone who has their act together. This in turn means Suppliers will take less liberties with you and your products. When you send a plain email order it signals to your Supplier that if you can't even be bothered to send an actual Purchase Order, what are the chances that you're going to do a Third Party Inspection?

Send a Product Specification Document

Here's the most important thing to do for your products: with your purchase order attach a Product Specification document. This sounds complicated and half of you reading probably just clicked away but it can be really simple. A Product Specification document is simply a document that defines what exactly a non-crappy product looks like. This document is both for your Supplier to use as a quality assurance document and also for a Third Party Inspection company to use. Also, if problems occur with an order your Supplier can't give any excuses of “we didn't know”.

Why is this document so important? Because if you don't specify something your Supplier will assume it's open for interpretation.

I'll give you an example of types of things I include (again, in my course I also give you a template). I'm in the process of importing a type of vehicle awning. I've never imported this item before so I'm not really sure where a Supplier will start to cut corners on or make careless mistakes. However, I've made several different requests tom my Supplier, mostly for the packaging and labeling. I want all of these specifications listed in one single document opposed to being scattered throughout a bunch of Skype messages. This document includes specifications like:

- The location and size of my logo printed on the awning

- The color of the inner box

- The requirement of my bar code and label to be printed on the box

- A picture of all of the installation hardware that needs to be included

- The requirement of my instructions to be included with the item

- The actual color of the awning itself (brown)

- The material type we've agreed on (420D polyester)

- They diameter of the aluminum tubing being used (7/8″)

All of this might sound elementary but it's absolutely critical – if you don't include requirements like listed above, I assure you that at some point your Supplier will do things like change the color of fabric from brown to grey because they had surplus grey fabric, forget to bar code the items, or miss hardware pieces. If you requested a sample from your Supplier, simply describe this sample fully in a one or two page document. You don't need to get overly technical – saying “red” instead of an exact Pantone color code is more than adequate.

If you want to be really lazy, you can just write points like above at the bottom of your Purchase Order – but please please please include as many specifications as possible in either a Product Specifications document or at the bottom of your Purchase Order!

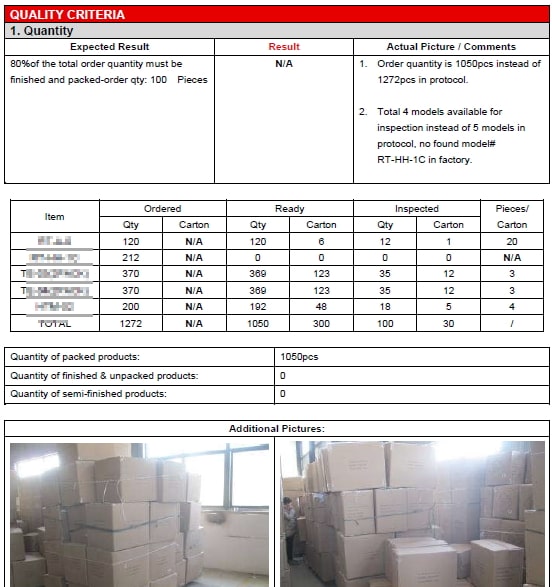

Perform a Third Party Inspection

You need to perform a Third Party Inspection at least sometimes. Ideally you would do it on every order, but for many smaller Amazon sellers who are importing low 4 figure orders, this isn't realistic.

Third Party Inspections through a company like Asia Inspection are cheap – around $300. By doing an inspection you can both verify that the products meet the criteria listed by you in your Product Specification document and you can also keep your Supplier on their toes.

See my post, How to Do a Third Party Inspection (and Why You Need One) for more detailed instructions.

Review Your Products, Revise Your Product Specifications Document

Once you receive your first order of products, review them thoroughly. Look for anything that needs changed on the next order and record it in your your Product Specifications document.

As you start to sell items, you may hear feedback from customers. An example I ran into recently was customers were complaining some of the mounting hardware for one of our products rusted easily. It's not the biggest deal in the world as it is mostly a minor aesthetic issue but on future orders I had the hardware switched to stainless steel hardware. I, of course, recorded this change in my Product Specifications document so my Supplier (and me) remembers to have this change made.

What to Do When You Receive Crappy Products

So what do you do when you receive some crappy products?

First off, it's important to understand that no shipment will ever truly be defect-free. There's actually a set of industry standards around quality inspections and the generally accepted principal is that on an order of products there should be:

- 0% defects that could result in someone or something getting hurt (i.e., faulty brakes on a bike)

- 2.5% major defects which would result in a customer rejecting the item (i.e. a tear on the bike seat)

- 4.0% minor defects where a trained eye would notice but most customers wouldn't care (i.e. a scratch on the bike seat).

Common practice dictates that if you receive 2.5% or less major defects on a shipment that the Supplier doesn't compensate you for it. There's no quicker way to burn bridges with a Supplier then to complain that you received one faulty item on your order of 10,000 widgets.

For me, if I receive more than 2.5% major defects, I raise the issue with my Supplier and ask for replacements on the next order. (Suppliers love this too because it guarantees a next order) Trying to get a refund from a Supplier is like trying to get blood from a stone so it's not even worth trying.

Conclusion

This wraps up the two part series on how to avoid scams in China and how to avoid crappy products.

Scams are completely avoidable in China but crappy products are a lot less easy to avoid. It's important to recognize that quality normally fade over time, it doesn't just occur suddenly and violently. It's like cancer and the sooner you catch it the better. And even better, you should avoid getting cancer in the first place through the use of a Product Specification worksheet and performing the odd quality inspection.

Have you ever experienced quality fade when importing from China? What, if any, recourse did you take with your Supplier? Please share in the comments section below.

[…] How to Avoid Crappy Products When Importing from China […]

Good article Dave, after dealing with so many suppliers I’ve figured there is no perfect supplier in the real world, people will always make mistakes we just need to make sure we can work it out when I got a problem.

BTW you got a 404 issues on this page: [FIXED] https://www.ecomcrew.com/a-secret-weapon-for-doing-competitor-and-supplier-research/

You’re right – and not every Supplier is right for everyone. Thanks for the heads up on the 404 – we still have some transition hiccups to get over.

hi David, I plan to sell on Amazon US but I am living in Australia. If a customer asks for product return and refund and I don’t have a warehouse to accept the returned products. what should I do? do I have to get a place to accept returned products?

Amazon will handle most of the returns. For the other returns you’ll likely have to have them disposed (it’s just a cost of doing business unfortunately).