How to Ship Full Containers (FCL) Overseas Direct From China to Amazon FBA in 2022

Once your shipments get large enough and you're shipping full containers you may start to consider shipping full containers into Amazon FBA. If you're shipping LCL you may want to ship to Amazon FBA as well.

One of the things I strive for as much as possible with my new company is having as lean and quick shipping and logistics as possible, and shipping direct solves a lot of that. In this article, I'll describe exactly how you can ship containers direct to Amazon.

Topics Covered

Related Podcast: Episode 26: Sourcing Inventory From China and the US, Part Three

Related Article: FCL Freight vs. LCL Freight

Pros and Cons of Shipping Direct to Amazon

Pros:

- Quicker shipping time than shipping to a middle man and then to FBA

- Save on the cost of a 3PL (or your own warehouse)

- Less time required to prepare the shipments

- Less handling of your items

Cons:

- Can be difficult to get freight appointments with Amazon

- Higher Amazon storage costs

- No domestic inspection before it hits Amazon

- No partnered carriers

The big advantage to shipping direct to Amazon is you save on shipping time. It is almost always going to be quicker to ship a container directly into Amazon than have it stop off at a 3PL in between (not to mention you save all the freight costs of delivering it there and the 3PL costs). I'll go into the full-time considerations below. After a time though, you will save significantly on 3PL costs (or your own warehouse costs), somewhere between $500-2000 per shipment in my estimation. Finally, shipping direct into Amazon in a sealed container eliminates a significant amount of handling (3PL, partnered carriers, etc) of your products. The more products are handled, the more chances for breakage, loss, etc.

The big disadvantage of shipping direct to Amazon is that you have no chance to inspect your products before they hit Amazon. You have to have complete trust in your supplier (that they won't screw anything up) and your products (that they won't have any catastrophic issues) to ship this amount of volume directly into Amazon. If there is a catastrophic issue like your supplier getting your bar codes mixed up, you could lose a lot of money retrieving your inventory from Amazon and fixing the problem.

Money Considerations – Is It Worth It?

The big question is, is it cheaper to ship a full container direct to Amazon?

In my experience, where you save the most money is through 3PL costs. My first time doing a full container I thought I would save a lot of money by shipping my container directly from Seattle (also the location of my 3PL) and then put directly on rail to Illinois, the location of the Amazon FBA warehouse I was shipping to. In reality, the additional rail costs of going from the Port of Seattle to Illinois compared to the cost of partnered carrier from my Seattle 3PL to Illinois were nearly the same probably because of the deep discounts you get with Amazon partnered carriers. The conclusion is that there are very little financial benefits on overland freight from shipping a full container directly to Amazon if the container is going to a non-West Coast fulfillment center.

Where you will save a lot of money on overland costs is if you are shipping to a West Coast Amazon warehouse like ONT8 in California in which case you will save a lot on overland freight due to the proximity of the Amazon warehouse to the port.

Where you really save money is on the cost of a 3PL or your own warehouse. If you have your own warehouse your costs are probably cheaper than a 3PL but not by much. When using a 3PL or your own warehouse you get the advantage of using Amazon partnered carriers but you lose on the container unloading charge, palletization charges, and any pick/labeling fees. I've put together an interactive spreadsheet below that you can use to figure out how much money you can save by shipping directly to Amazon. In most cases, I think you will save anywhere from $500-$2000.

Time Factors – Is It Worth It?

There's one important other consideration when shipping into Amazon aside from money: time, both your time and the time it takes to receive a container into Amazon.

Time Receiving by Amazon

When you ship a container directly into Amazon you are saving many days in time as opposed to shipping to a middle man first in between. If you ship to a middle man first you will lose time on the following:

- Trucking the container from the port to your middle man location

- Unloading the container

- Palletizing, labeling, etc.

- Partnered carrier pickup and transit time to Amazon FBA distribution center

My biggest bottleneck in the past has been my 3PL being overworked and not being able to prepare my shipment for a few days. Normally my 3PL wants at least 2 or 3 days' notice before having the Amazon partnered carrier pick up the pallets. In my experience, you'll save 3-10 days in transit time by shipping directly to Amazon.

Time Preparing Shipments

How often do you feel like your job as an ecommerce business is simply preparing Amazon FBA shipments? By shipping all your inventory in one big shot to Amazon you save all of the time that goes with preparing Amazon shipments.

Full Container Loads Requirements

- Everything needs a carton label

- Amazon prefers items to be palletized but doesn't require it (i.e. the container can be floor stacked)

- An appointment with Amazon

When shipping into Amazon everything technically still requires a carton label. The good news is that if you're shipping a floor stacked container you don't need pallet labels.

Amazon will allow you to floor stack a container, although they say they prefer a container to be palletized as it reduces delays. In my opinion, any delay will be negligible and there's no need to palletize a shipment.

Finally, Amazon requires your carrier to make a booking appointment with Amazon. Most carriers are now familiar with doing this. The big problem is lack of appointments with Amazon. Your carrier may be waiting days to get an appointment and each day of storage for a container is around $100 – those delays can quickly cut out your savings on shipping containers direct.

The Multiple Warehouse Conundrum: At this point, some of you may be thinking, “But Amazon requires us to ship to multiple FCs” and most of you probably do not want to turn on inventory placement. The good news is that Amazon does appear to be relaxing how many FCs they require you to send shipments to and often now you will, by default, have your inventory directed to only one FC (especially if you avoid mixing different size tiers of items). There are other white hat and grey hat ways to get around the multiple FC issue but I won't cover it here.

How to Ship a Full Container

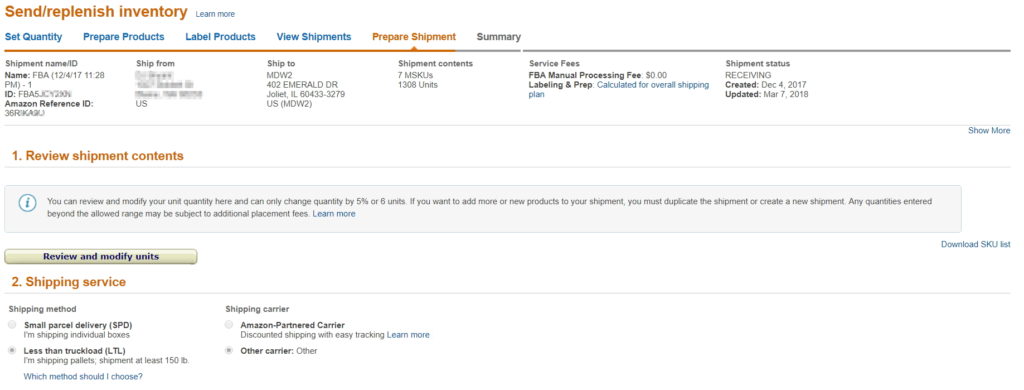

Prepare Your Shipment within Seller Central

The first step is to prepare your shipment in Amazon Seller Central. I'll assume you know the basics of this and only cover the intricacies here.

Ship from Location: You can put anything in here from your supplier's address in China to your home address. You're not using a partnered carrier so it doesn't appear to change anything.

Shipping Service: Here you want to select “Less than truckload (LTL)” and “Other carrier: other”. You use this option for LCL or FCL (despite it only saying LCL).

Next, you specify the number of cartons and items as normal, print the labels, and provide them to your supplier in China.

Provide Your Supplier the Labels

Your supplier will need to apply carton labels to every master carton. Moreover, if you're being nice to Amazon and palletizing your container you should stick pallet labels on your pallets, although I know people who do not apply pallet labels and in reality, it should cause you no problems.

Arranging the Sea Shipment

The easiest way to prepare the actual shipment of your goods is to have your freight forwarder arrange door-to-door service, meaning they pick up the container in China (whether at the port or at your supplier's factory) and arrange for shipment to the Amazon warehouse. If you're shipping to an inland Amazon distribution center like Illinois (and you probably will be unless it's in California) your forwarder will probably ship to a West Coast seaport and then put your container on rail.

Shipping from the U.S. Port to Amazon Distribution Center

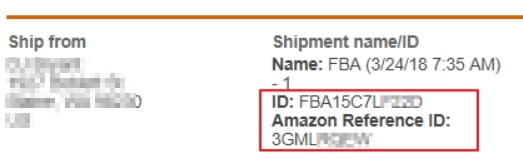

Completing the FBA Booking Form

When shipping into an Amazon Distribution Center the biggest difference between using an Amazon partnered carrier is that you will need to complete an Amazon FBA Booking Form that you will give to your forwarder. This form is very simple and you simply need the Amazon FBA reference number (see below). It's the same form if you have ever shipped via LTL without an Amazon partnered carrier. Your merchant name is just your display name.

Getting an appointment at Amazon is potentially the biggest problem with shipping direct into Amazon as Amazon is notoriously stingy about not giving convenient appointments. Making the appointment is the responsibility of your freight forwarder, but if they cannot get an appointment quickly you'll face $100+ per day in storage charges from your forwarder. Amazon appears to be getting better about giving out appointment times though so hopefully you do not have any problems.

Ultimate Consignee Information

When you give your customs broker your shipment information they will also likely need Amazon's tax ID in order to list them as the ultimate consignee. Your customs broker can email sellerimports@amazon.com and get this ID (Amazon Seller Support actually gave this to me directly although they state they only give it to registered customs brokers). Don't listen to anywhere that says Amazon will not allow you to list them as the Ultimate Consignee as they will (they will not, however, allow you to list them as the Importer of Record).

Palletized Containers with Partnered Carriers – A Hybrid Approach

There is a hybrid approach I have been experimenting with: having my Chinese suppliers palletize and label FBA shipments, shipping them to a 3PL and then into Amazon FBA with a partnered carrier, either immediately or in the future.

There are some advantages to doing this:

- You can use partnered carriers

- You can inspect your shipment in America

- Cheaper unloading from 3PL and no labeling costs

- Delay shipments into FBA to avoid unnecessary storage fees

- Can ship to multiple Amazon FCs

By palletizing your shipments you will reduce your 3PL costs (most charge less money for unloading of palletized containers). Also, if Amazon divides your shipments into multiple warehouses this is no problem and you can use partnered carriers. You can also save money by storing pallets at a 3PL instead of Amazon (Amazon FBA storage is 2-5x more expensive than most 3PLs). As of now (or at least as far as I know) Amazon has no restriction on how quickly you need to ship a shipment into Amazon after you create the shipment. This means you can create a few shipments in January and ship them into Amazon in November if you want.

The big downsides are you will lose container space and you will have 3PL costs. The good news is that you will actually only lose around 4% storage space if you ship stackable pallets in a container if your supplier packs efficiently. Assuming sea costs of around $1500, this means you only lose around $60 on lost space. Make sure your supplier uses heat-treated export-ready pallets (and they will likely charge you for these).

If you want to ship LCL (Less than Container Load) from China, this is essentially the same way that you would do it.

Conclusion

This should give you everything you need to know about shipping full containers into Amazon. This article should also help you to determine if you should ship full containers into Amazon in the first place.

Do you have any questions about shipping into Amazon? Or do you have any experiences of your own? Comment below.

Super helpful – thanks Dave. Is it also possible to ship containers directly to Amazon FCs in the EU? If so, are the shipping requirements around pallets/configurations any different?

Hi Dave,

Many thanks for this website, and excel sheets. I am going to be a new vendor at Amazon EU (DE and UK). Are Amazon fees and requirements the same there as well? Is there a resource/website you can direct me to? I am planning to produce food products in Peru and Turkey and sell them on Amazon.

Thanks in advance,

Maria

Some fees (i.e. FBA fees) and other requirements are a bit different. Unfortunately I’m not sure of a great place to point you :-(

It sounds like appointment availability is improving but to your point, that doesn’t necessarily guarantee a speedy unloading process. Do you have any insight/resources you could share on how to navigate that issue? Is it typical for the container to be unloaded within the appointment window or could it possibly wait hours/days? Is the seller responsible for ensuring that the container gets fully unloaded and if so, what role does the carrier/freight forwarder play in that process?

Hi Ben,

Within the last year, all of our containers are unloaded within 1-2 hours of the appointment window (which still means a bit of wait time, but not much). It is possible to drop the container off at Amazon and for the driver to pick it up when done, which avoids potential wait times, but incurs two delivery fees. Amazon does all of the unloading so neither the seller nor carrier play a role in that.

Super helpful – thanks Dave. Is it also possible to ship containers directly to Amazon FCs in the EU? If so, are the shipping requirements around pallets/configurations any different?

Thanks a lot Dave, this article is very helpful.

When we are allowed, I am planning to get a full container of products from China to Amazon warehouse in Italy (where I live).

I have a question if you can please answer it:

I don’t have a customs broker, is there a freight company that does door to door FCL and charges me for the customs fees?

Thanks,

Sayed

Many/most freight forwarders also offer customs brokerage services.

Hi Dave,

Thanks for your explanations on shipping to Amazon. Unfortunately, my suppliers don’t put boxes on pallets and ship them in containers. So my questions are:

1. If I ship a 20′ container with my products (ie. 300 boxes with amazon labels), would I be able to ship the container directly to Amazon warehouse and would they hand-bomb the boxes or do I have to put them on pallets before shipping to Amazon.

2. If I need to put them on pallets to ship to Amazon, how would I do that without bringing the container to my warehouse? Are there any trucking companies that provide this service (palleting and labelling)?

Regards,

Sadat

1. They’ll accept floor loaded containers. 2. Best option is to have your supplier do it. Most suppliers should agree to do this but are going to charge you extra for the pallets (up to $50 per pallet).

Hi Dave,

Great Article!!

Do you have any recommendations for 3PL warehouses you worked with and are familiar with Amazon requirements?

Best,

Tal

Check out: https://www.ecomcrew.com/the-ultimate-guide-to-finding-and-choosing-a-third-party-logistics-company-or-3pl/

Great post Dave .. We only send sealed containers, like you Im trying to reduce this cost and streamline who we use to do this. Ill be interested if you are still using flexport or other..

Im finding we are paying around $1.50 per unit 5250 units per 20 foot container to get into amazon .. Id like to get this down to $1 –

The 3 pl Im using charge around $1600 to unpack , barcode up and palletise + create shipping into amazon ..usually 3 FC – I can reduce costs on barcodes by having my manufacturer do this now ..

Its a fine line – but I def think we can reduce some costs ..

thx

Matt

thx

Matt

The 3PL costs seem really high.

Thanks Dave, Great Article. Are you available to be hired as a consultant for a newbie ? Or maybe even just a quick phone call? :)

I am having a figurine produced in china and then plan on selling on amazon and doing FBA. The shipments would just be boxes of the same figurine . No variations on size, color , anything really. Will that make the labeling easier and chances of something going wrong in shipping decrease at all/ dramatically? Manufacturer is working up a quote currently that included shipping door to door but thinking going direct from factory in china to LA fulfillment center makes most sense. Do you get to pick which fulfillment center to send to or does amazon assign it.. Thanks so much!!!

Tim

Hi Timothy,

Amazon will assign the fulfillment center.

With EcomCrew Premium you get unlimited 1 on 1 email support from us, access to bi-weekly webinars and our private discussion area. It’s not quite consulting but it should be able to help you through any questions you have :)

Hi Dave,

We are very interested in sending a full container to Amazon from our suppliers in China. However, we have heard that many Amazon’s fulfillment centers are busy and not getting appointment in time. From your experience, how quickly can you get the container delivery appointment? Even though you got an delivery appointment, that doesn’t mean Amazon will unload the container in a timely manner and will result in drivers’ waiting charge. From your experience, average how long does Amazon take to unload a 20′ container?

Lately we’ve been getting near instant delivery appointments (and for sure within the 5 days free that Freight Forwarder gives you). Earlier in the year we we had a 9 day wait, meaning we got stuck with 4 days of storage. They’ve been pretty good as of late though.

This is an amazingly resourceful write up. Thank you.

Hi Dave, thanks for this write-up. I am a first timer who is just nearing the first production run phase of my startup. I have quite a few questions. If I plan on selling on Amazon solely to start, is that a good move? What did you do your first run? I live on 5 acres of land in Central Washington State and could offload here, but should I? My product is somewhat large like that of a camping chair. I want to make the right moves from the start and would love to hear from your experience.

Hi Kasandra,

I’m personally all in on Amazon – you can listen to the podcast here for the pros and cons of that: https://www.ecomcrew.com/episode-73-should-you-go-all-in-on-amazon-or-not/. If you’re going to hold your inventory for less than 6 months than storing everything at Amazon may make the most sense. If you store things at your place, it’ll save you money but it could be a monster PITA and it could be expensive, especially for the cost of logistics your residential address.

Dave,

How do you get a shipment with the right quantity to fill a full container out of Amazon’s inventory split algorithm? It seems like even if you get one FC that’s close to a container load, you would still be stuck doing multiple LCL shipments to the other FCs.

Am I missing something?

Hi Jody,

If it’s a single SKU (or even a small number) and all standard size items, Amazon is a lot better now at sending them to one FC. If it’s oversize, no way. If you’re still getting multiple FCs with a small number of standard size items then you’re at Amazon’s mercy. To be completely white hat, you will have to ship those remaining shipments at some point, although it can be months and months down the road. The other option is to turn inventory placement on.

Hi Dave,

I like your articles. With regard to product barcodes. Does Amazon supply barcodes for each new product, or where does one get them.

Hi,

Refer to this article here: https://www.ecomcrew.com/everything-you-need-to-know-about-barcoding-your-products/

Thanks Dave.

This advice is a lot of help.

Best regards

John

Happy to help :)